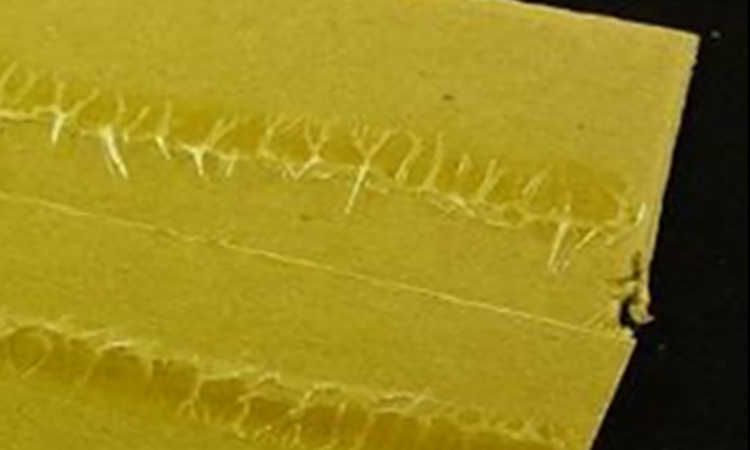

Torn labels

The problem

The bottles arrive at the boxer or warehouse with the labels broken.

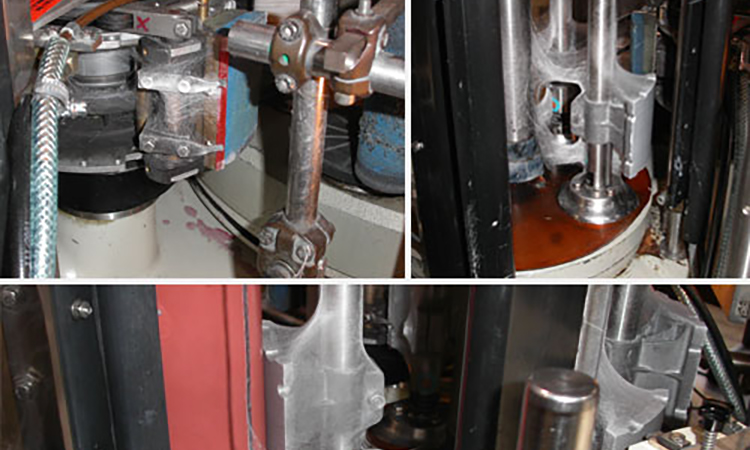

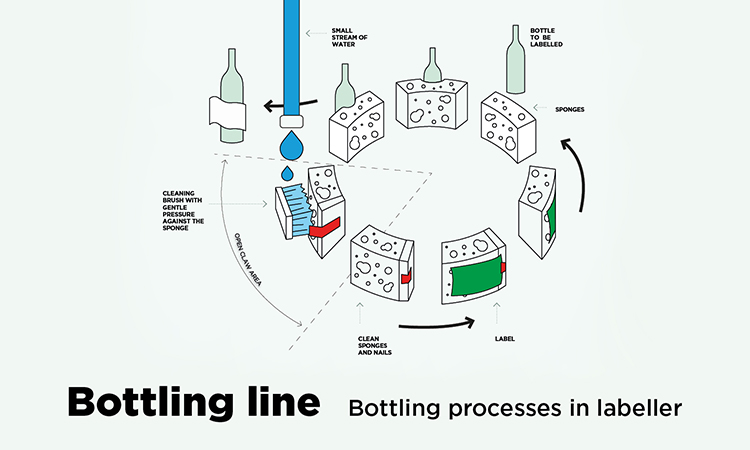

The origin of the problem

The problem may be caused by one of the following variables not being adequate :

The characteristics of the paper in terms of absorption capacity and wet strength are fundamental parameters.

Additionally, the initial tack of the adhesive and its evolution in the wet are also decisive.

On the other hand, the conditioning of lines and conveyors has to be adequate.

In short, the working speed of the labeller and case packer must be consistent to achieve optimum tension between bottles.

Finally, it is important to know the distance between the labeller and the packer, to understand what kind of performance the adhesive should have.

The solution

By studying all these variables we can identify how to solve the problem. In addition to all these variables, it is essential to know the temperature of the bottle, the environmental temperature, as well as the temperature of use of the adhesive to know which adhesive is optimal and how to use it.

If you need help contact us with just one click